2026 Buyer’s Guide: How to Choose a Reliable Vehicle CNG Cylinder Manufacturer?

Release time: 2025-12-29

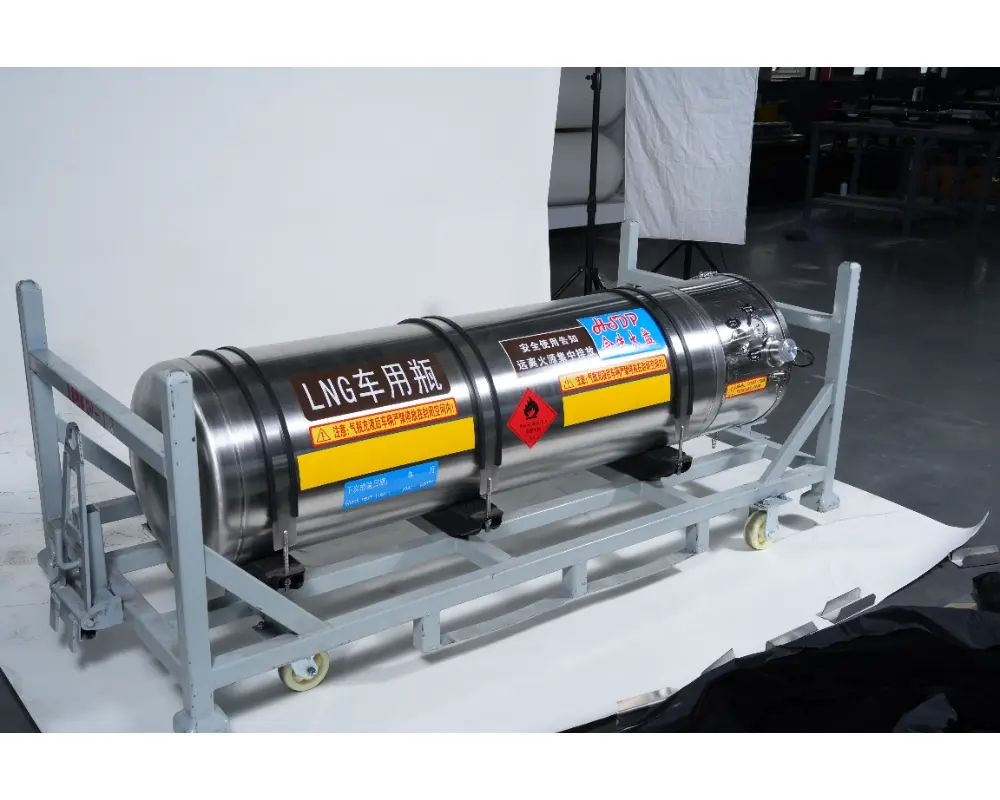

CNG (compressed natural gas) vehicles have become the preferred choice for energy conservation and emission reduction in commercial fleets and private cars. However, as high-pressure containers, the safety and performance of CNG cylinders directly affect the vehicle’s service life and occupant safety.

What dimensions should you focus on when choosing a Vehicle CNG Cylinder Manufacturer?

Quick Decision Summary: 4 Core Indicators for Selecting CNG Cylinders

The following four dimensions are the benchmarks for evaluating suppliers:

- Certification Standards: Compliance with international standards such as ISO 11439 or ECE R110.

- Material Types: Selection of Type 1 (Steel) through Type 2 (Hoop-wrapped) cylinders based on vehicle type.

- Safety Devices: Must be equipped with high-quality Pressure Relief Devices (PRD).

- Service Life: Ensure a design life of 15–20 years with comprehensive periodic inspection guidance.

1. International Certification: Authoritative Standards as the First Line of Safety

CNG cylinders are special equipment, and their manufacturing processes must follow strict international specifications.

- ISO 11439: The global standard for high-pressure cylinders for the on-board storage of natural gas as a fuel for automotive vehicles.

- ECE R110: European regulation concerning the approval of specific components of motor vehicles using compressed natural gas (CNG) and/or liquefied natural gas (LNG).

- The HSDP Advantage: As a professional Vehicle CNG Cylinder Supplier, all HSDP products are manufactured strictly according to international safety standards, ensuring global compliance and safety.

2. Cylinder Type Selection: Balancing Performance and Weight

Different cylinder types suit various vehicle requirements.

| Cylinder Type | Structure & Material | Advantages | Application Scenarios |

| Type 1 | All Steel | Lowest cost, extremely mature technology | Buses, Trucks, Heavy construction vehicles |

| Type 2 | Steel Liner + Hoop-wrapped fiber | Weight reduced by ~30% vs Type 1 | Medium trucks, Logistics vehicles |

3. Manufacturing Process and Quality Control

Excellent manufacturers focus on more than just raw materials; they prioritize process details.

- Spinning Process: Ensures uniform wall thickness at the bottom and neck of the cylinder to avoid pressure concentration.

- Heat Treatment: Precise quenching and tempering processes significantly improve the fatigue resistance of the cylinders.

- Non-Destructive Testing (NDT): HSDP utilizes ultrasonic and hydrostatic testing during production to ensure every cylinder leaving the factory can withstand loads far exceeding working pressure.

4. After-Sales Service and Periodic Inspection Recommendations

CNG cylinders are not “install and forget” products. A reliable supplier provides:

- Periodic Inspection Guidance: Advising users to conduct routine inspections every 3 to 5 years.

- Safety Valve (PRD) Support: Ensuring the pressure relief device acts accurately in case of accidental fire or overpressure.

- Traceability System: Every cylinder should have a unique serial number to track production batches and inspection records.

5.Why Choose HSDP as Your Vehicle CNG Cylinder Partner?

HSDP is committed to providing high-performance on-board high-pressure gas storage solutions to global customers. Our product line covers multiple specifications from traditional steel cylinders to modern composite cylinders, featuring these competitive advantages:

- Lightweight Design: Effectively reduces vehicle dead weight and improves fuel economy.

- Ultimate Safety: Passed rigorous tests including impact, fire, and gunfire tests.

- Customization Capability: We provide multi-cylinder installation solutions tailored to the installation space of different vehicle models.

FAQ: Common Questions on CNG Cylinder Procurement

Will using Type 2 cylinders really save my fleet money?

Yes. While a Type 2 cylinder is slightly more expensive than a Type 1, it’s about 30% lighter. This means you can carry more cargo per trip or reduce fuel consumption when empty. For long-haul logistics customers, the extra cost can typically be recouped within 12-18 months through fuel savings.

Is it safe if the fiber-wound layer of a Type 2 cylinder is scratched?

As long as the scratch depth is within the standard allowable range (detailed in the HSDP inspection manual), it’s generally safe because the internal steel liner still provides pressure support. However, regular inspection by a professional is necessary.

What are the advantages of HSDP’s Type 1 cylinders compared to other brands on the market?

We use higher-standard chromium-molybdenum steel and undergo a precise overall heat treatment process. This makes our Type 1 cylinders slightly lighter than ordinary cylinders while maintaining strength, and also provides a longer fatigue life.

Can these two types of gas cylinders be used in cold regions?

Yes. The steel is highly adaptable to temperature. HSDP gas cylinders are typically designed for a temperature range of -40°C to +65°C, fully meeting the operational requirements in extremely cold or tropical climates.

If you would like to learn more about the detailed specifications of Type 1-Type 2 CNG gas cylinders or obtain a customized quote, please feel free to contact us.

Tel:+8615375178899 | +8615375178899