A Deep Analysis of LPG Cylinders vs. LNG Cylinders for Automotive Use

Release time: 2025-07-21

With the rapid development of clean energy vehicles, Liquefied Petroleum Gas (LPG) and Liquefied Natural Gas (LNG) have garnered attention as key alternative fuels. Among the crucial components for storing these fuels—automotive gas cylinders—there are significant technical differences between the two, which go beyond just the names of the fuels.

The Role of Medium Characteristics in Core Design

High-pressure Ambient Temperature LPG vs. Cryogenic Low-pressure LNG

- LPG Cylinders: Essentially high-pressure vessels. LPG (mainly composed of propane and butane) must be pressurized to approximately 1.6–2.2 MPa at room temperature to remain in liquid form. The cylinders are made from high-strength carbon steel, with a relatively simple structure focused primarily on pressure resistance.

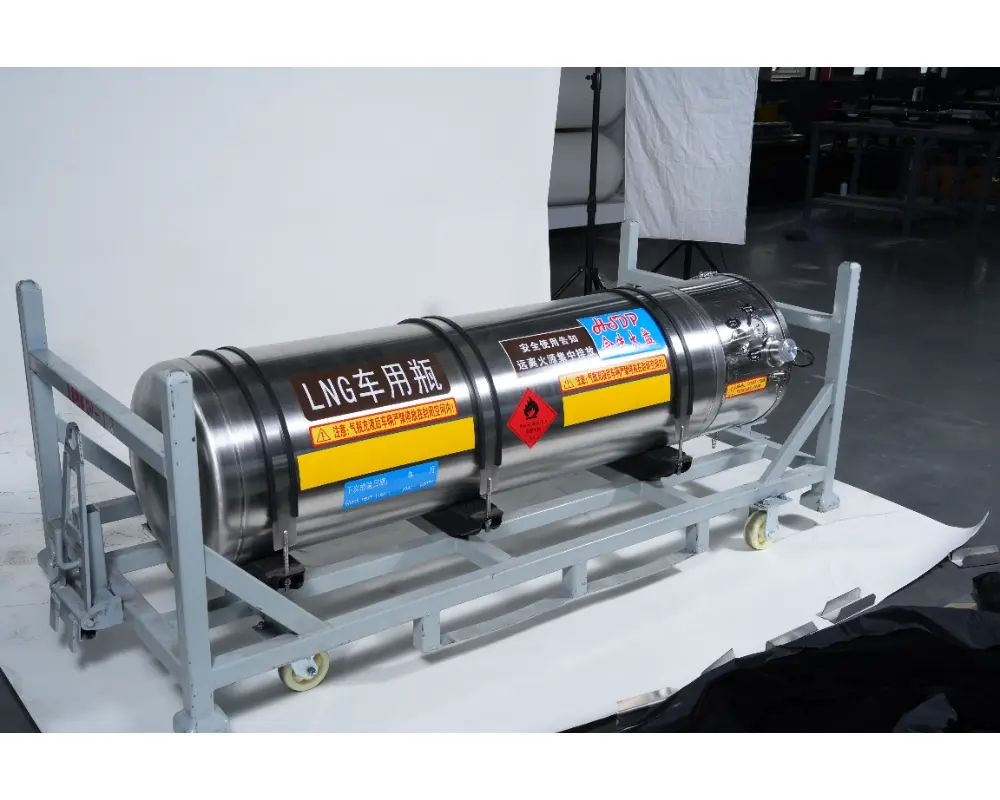

- LNG Cylinders: The core of LNG cylinder design lies in ultra-low temperature insulation. LNG (mainly composed of methane) must be maintained at a temperature of around -162°C to stay in liquid form, with a relatively low operating pressure (typically 0.3–0.8 MPa).

LNG cylinders produced by leading HSDP companies employ a vacuum multi-layer winding insulation structure, similar to a “high-tech thermos,” to minimize the ingress of external heat, control the liquid’s evaporation, and ensure the safety of materials at ultra-low temperatures.

Technical Differences

- LPG Cylinders: Manufacturing focuses on material strength and welding techniques to ensure high pressure resistance and prevent leakage. Regular inspections mainly focus on wall thickness, corrosion, and valve sealing.

- LNG Cylinders: The technical complexity is higher. HSDP’s production of low-temperature LNG cylinders involves precise vacuum creation and maintenance, specialized low-temperature materials, multi-layer composite insulation materials, and the application of ultra-low temperature adsorbents. Even a small vacuum leak or failure in the insulation layer could lead to cylinder failure or safety risks. These cylinders are, in essence, high-tech products that combine cryogenic engineering, vacuum technology, and pressure vessel manufacturing.

Application Scenarios

Economic Cars vs. Heavy-duty Long-distance Vehicles

- LPG Cylinders: Due to their relatively simple structure and well-established refueling network, LPG cylinders are widely used in fields sensitive to cost and refueling convenience, such as taxis and small household cars.

- LNG Cylinders: With higher energy density and significant emission reduction benefits, LNG cylinders are ideal for long-distance heavy-duty trucks, large buses, and inland/coastal shipping fuel systems. HSDP, as a leading LNG cylinder manufacturer in Asia, provides lightweight designs and ultra-high safety standards, supporting the green transformation of these high-energy, long-distance transportation tools. The shipping industry places even more stringent demands on the insulation and safety of large LNG fuel tanks.

Safety and Regulations

- LPG Cylinders: The primary safety focus is preventing high-pressure leaks and physical collisions. Regulations require regular pressure testing and strict installation positioning.

- LNG Cylinders: The core safety concern is maintaining stable insulation performance under extreme low temperatures and preventing the risk of rapid phase transition (RPT). The design, manufacturing, and inspection standards (such as ISO 20519, EN 13458, GB/T 18442) are more rigorous, with particular attention to vacuum lifespan, static evaporation rate, overpressure protection, and collision safety.

Industry Insights:

Choosing between LPG and LNG is not just about the fuel but also about selecting a corresponding fuel storage system with distinctly different technological requirements. The manufacturing of LNG cylinders represents a high-tech level in the gas containment system field. HSDP, with over twenty years of experience, has built a true competitive edge in vacuum insulation and low-temperature materials.

As the “dual carbon” targets are pushed forward and the pressure for carbon reduction in heavy transport increases, LNG and its supporting high-performance cylinder systems—though more complex—are emerging with significant potential for emission reductions. HSDP, as an important R&D and manufacturing hub in Asia, will continue to enhance the safety and lightweight capabilities of LNG cylinders, providing key infrastructure support for the decarbonization of land and maritime transport.