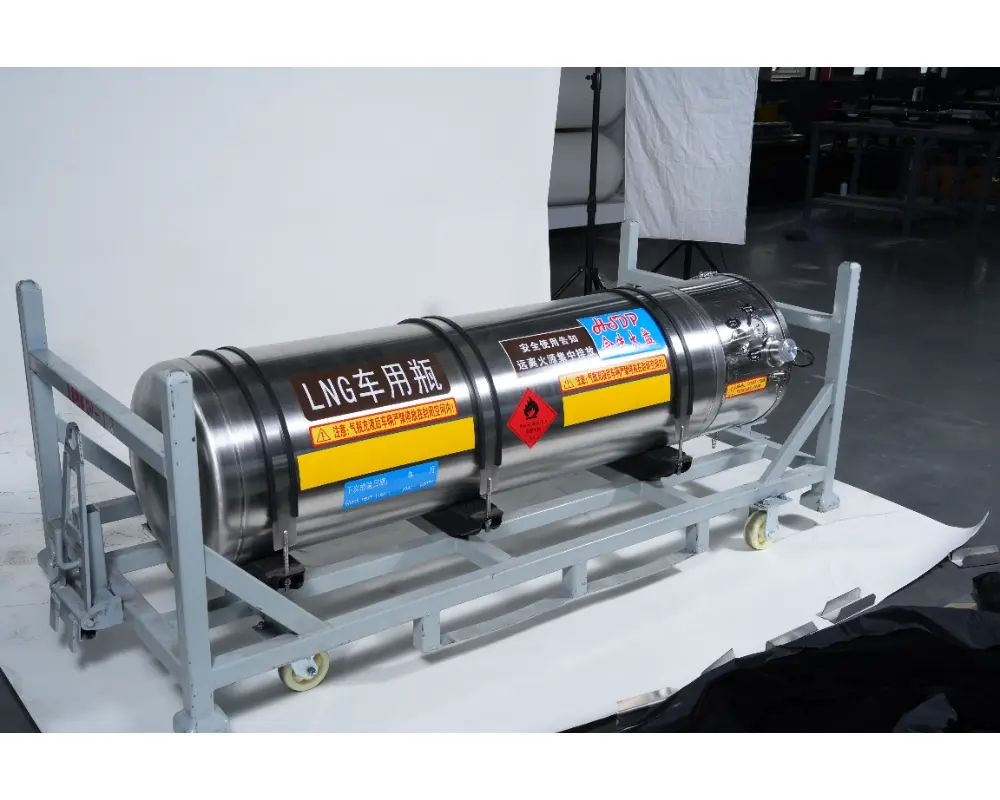

All You Need to Know About LNG Cylinders For Vehicle

Release time: 2025-10-13

Liquefied natural gas (LNG) as a vehicle fuel has become an important option for improving fuel economy and reducing pollution. As a key device for storing LNG, LNG cylinders for vehicle are playing an increasingly important role. In this article, we will detail the definition, technical features, application scenarios, and how to choose the right LNG cylinder for automotive use, helping you better understand this important product.

What are LNG Cylinders For Vehicle?

A LNG Cylinders for vehicle is an insulated pressure vessel designed specifically for storing cryogenic liquefied natural gas (LNG). It efficiently stores and safely supplies LNG. LNG cylinders use insulation technology to maintain LNG in a liquid state at -162°C, ensuring safe and stable use in the vehicle’s combustion system.

How LNG Cylinders Work

The working principle of automotive LNG cylinders is to store LNG at extremely low temperatures and convert it into gaseous natural gas through a pressure-controlled device for use in the vehicle engine. LNG is stored in liquid form in the cylinder and converted to gaseous form only when needed through gas pressure increase and temperature regulation.

Brief Description of the Working Process:

- Liquid Storage: LNG is kept in a liquid state within the cylinder at a temperature of -162°C and at extremely low pressure.

- Gasification: When needed, LNG is converted to gaseous natural gas through a pressurizing device.

- Combustion Supply: The converted natural gas is transported via pipelines to the vehicle engine, where it is burned to generate power.

Technical Features of Vehicle LNG Cylinders

- High Safety: Vehicle LNG cylinders utilize advanced composite materials, offering strong pressure and shock resistance, ensuring no risk of leakage or explosion during operation. Each cylinder undergoes rigorous quality testing and complies with international standards and certifications.

- Lightweight Design: Vehicle LNG cylinders utilize carbon fiber composite materials or glass fiber reinforced plastics, significantly reducing their weight. This lightweight design not only improves vehicle fuel efficiency but also increases vehicle load capacity.

- Long Life and High Durability: Vehicle LNG cylinders are typically designed for a 15-year service life and are highly resistant to corrosion and temperature fluctuations. They maintain stable performance even in harsh climates.

- Multiple Safety Protections: To ensure safe use, LNG cylinders for vehicles are equipped with multiple safety features, such as overpressure valves, temperature control valves, and leak alarm systems, ensuring automatic activation of protection mechanisms in abnormal situations.

Applications of LNG Cylinders for Vehicles

LNG cylinders for vehicles are widely used in various vehicles, particularly commercial vehicles and public transportation. The following are some key application scenarios:

1. Commercial Transport Vehicles

LNG fuel has become an important fuel for bulk cargo transport vehicles and long-distance trucks, offering the advantages of reduced emissions and fuel cost savings.

2. Urban Public Transportation Systems

In most cities, buses have begun using LNG instead of traditional fuels, which not only reduces carbon dioxide and nitrogen oxide emissions but also effectively reduces noise pollution.

3. Heavy Machinery and Engineering Vehicles

Heavy machinery and engineering vehicles typically require a large amount of energy. LNG can provide these equipment with stable power output and has excellent environmental benefits.

4. Ships and Marine Transportation

LNG cylinders are also widely used in ship fuel systems, making them an ideal choice for reducing carbon emissions and improving energy efficiency in the marine transportation sector.

How to Choose the Right LNG Cylinder for Vehicles?

When choosing a LNG cylinder for heavy duty vehicles, you need to consider the following factors:

- Quality Certifications and Standards

Ensure that the cylinder complies with international safety standards and certifications, such as ISO 11439. These certifications guarantee the cylinder’s safety and reliability. - Material Selection

Choose cylinders made of carbon fiber, composite materials, or high-strength steel. These materials significantly reduce cylinder weight while increasing pressure resistance. - Volume and Pressure Range

Select a cylinder with the appropriate capacity and pressure range based on the vehicle type and fuel requirements. Different vehicle models and usage scenarios require different cylinder designs. - Supplier Service and Support

Choose a supplier with a good reputation and comprehensive after-sales service. High-quality after-sales service ensures timely technical support and maintenance for your LNG cylinders throughout their operation.

As core equipment for the storage and supply of liquefied natural gas (LNG), vehicle-use LNG cylinders are becoming the preferred fuel storage solution for an increasing number of commercial vehicles, buses, and heavy machinery due to their high safety, lightweight design, and environmental benefits. Choosing high-quality LNG cylinders for vehicles not only ensures a safe and stable fuel supply, but also helps your business achieve environmental goals and reduce operating costs.

If you have any questions about LNG cylinders for vehicles, or would like to learn more about them, please feel free to contact our professional team. We will provide comprehensive technical support and services.

Frequently Asked Questions (FAQs)

Q1: What is the service life of LNG cylinders for vehicles?

A1: LNG cylinders for vehicles are generally designed to last at least 15 years and are highly durable and corrosion-resistant.

Q2: What safety measures are in place for LNG cylinders for vehicles?

A2: LNG cylinders for vehicles are equipped with multiple safety valves, temperature control valves, and pressure protection devices to prevent leaks or explosions during use.

Q3: What factors should be considered when purchasing LNG cylinders?

A3: When choosing LNG cylinders, consider factors such as the cylinder’s quality certification, material selection, volume and pressure range, and the supplier’s after-sales service.