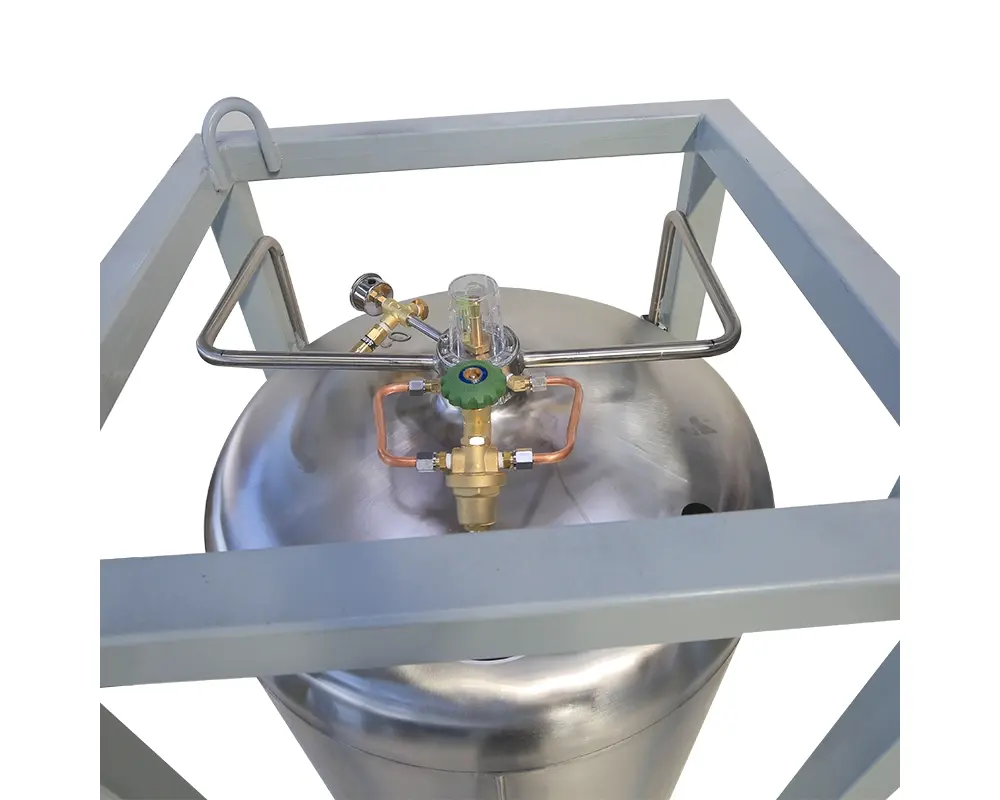

The welded insulated gas cylinder is a gas storage device manufactured using high-vacuum multi-layer insulation technology and precision welding processes. It is primarily designed for the safe storage and transportation of “cryogenic liquefied gases” (such as liquid oxygen, liquid nitrogen, liquid argon, LNG, etc.).

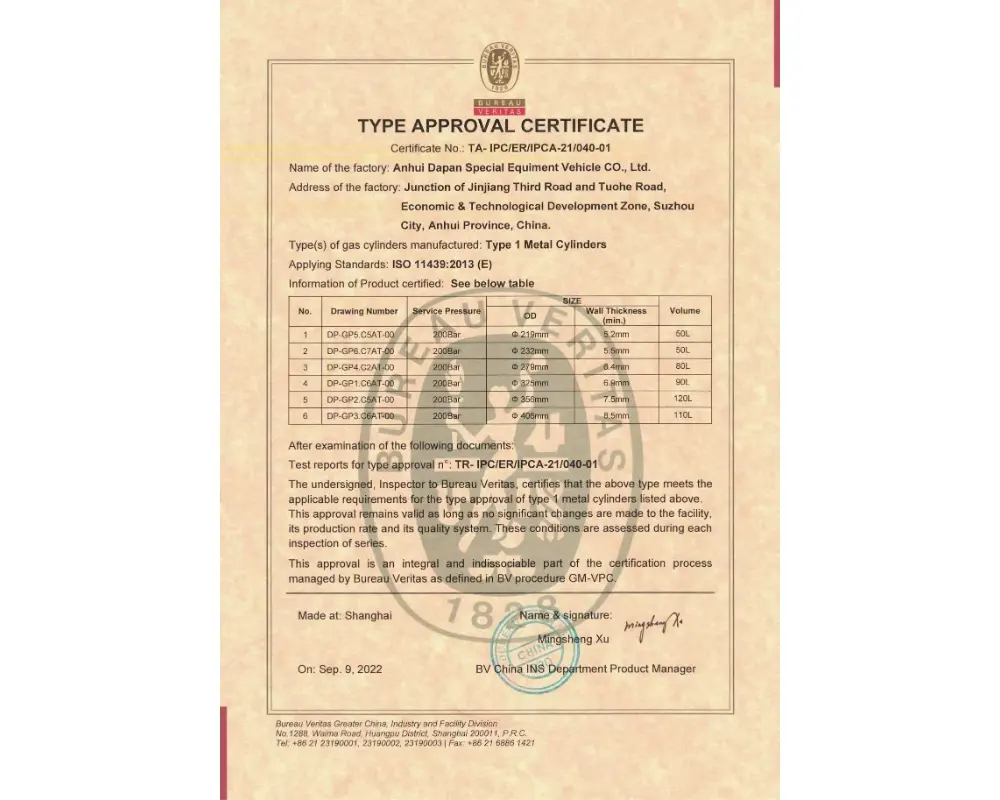

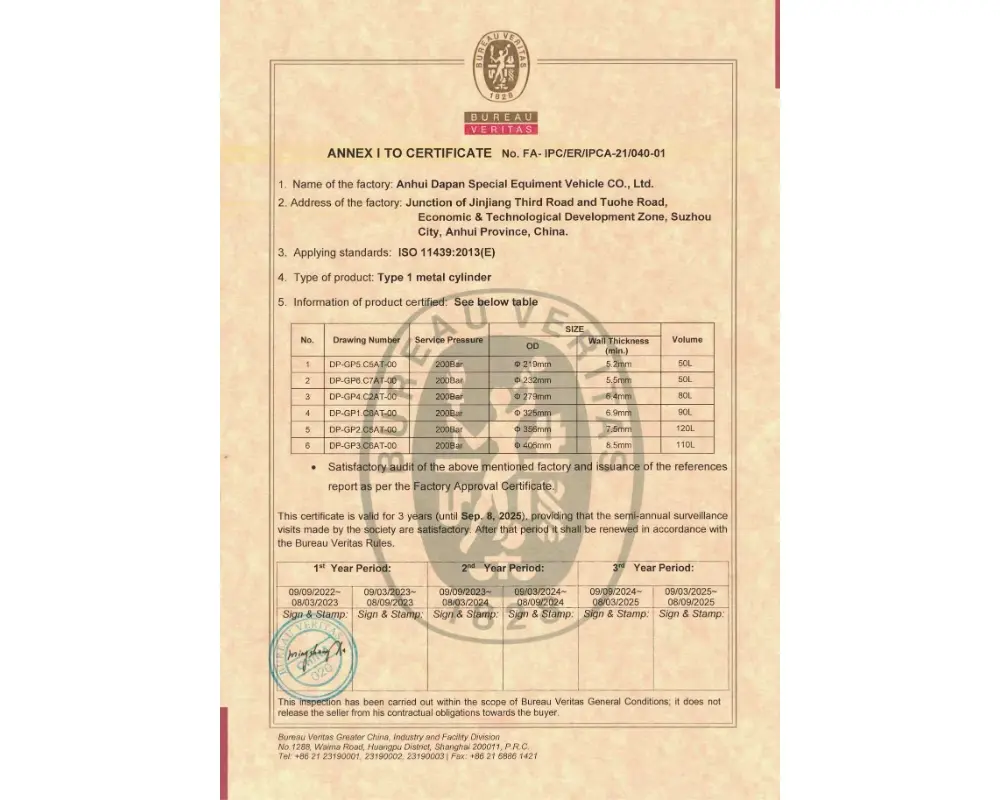

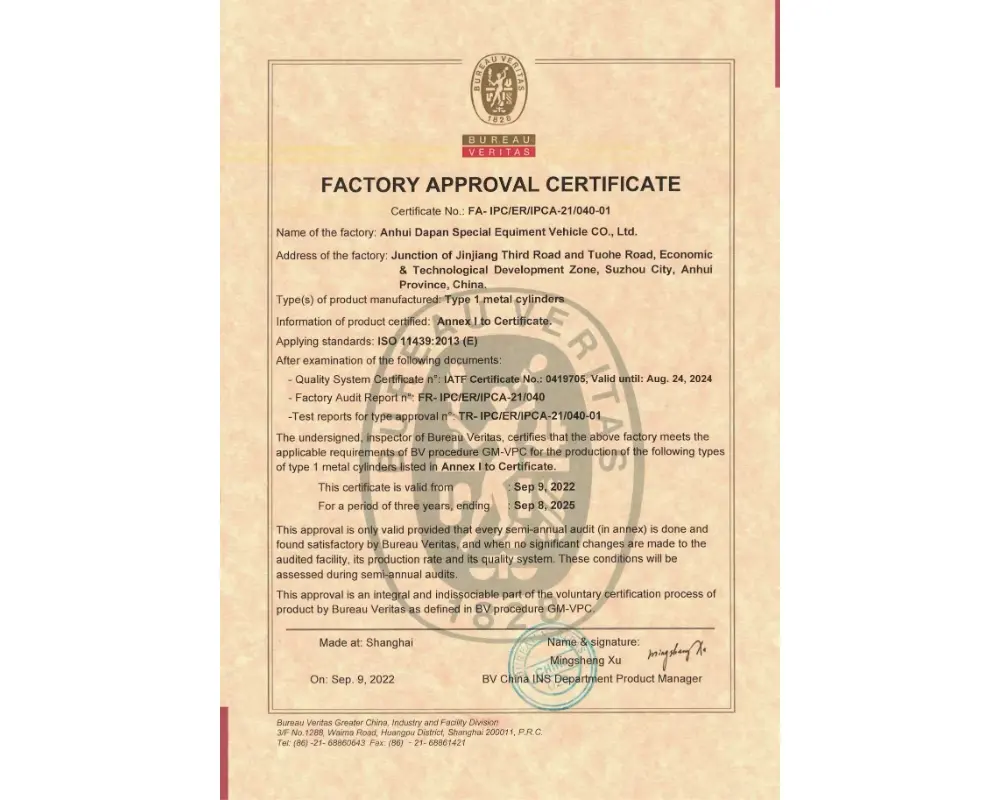

| Product standards: | ISO11439、ECER110 |

|

Product model: |

DPW650-500-3.45 |

|

External dimensions (mm): |

840×1030×2050 |

|

Empty weight of gas cylinder (Kg): |

469 |

|

Working pressure (MPa): |

3.45 |

|

Base structure: |

Frame style support structure |

.png)

.png)

[excel | 2025.05.06]

Precision-Engineered Welded Cryogenic Cylinders

[excel | 2025.05.06]

Precision-Engineered Welded Cryogenic Cylinders